PRODUCTS

SENSORS

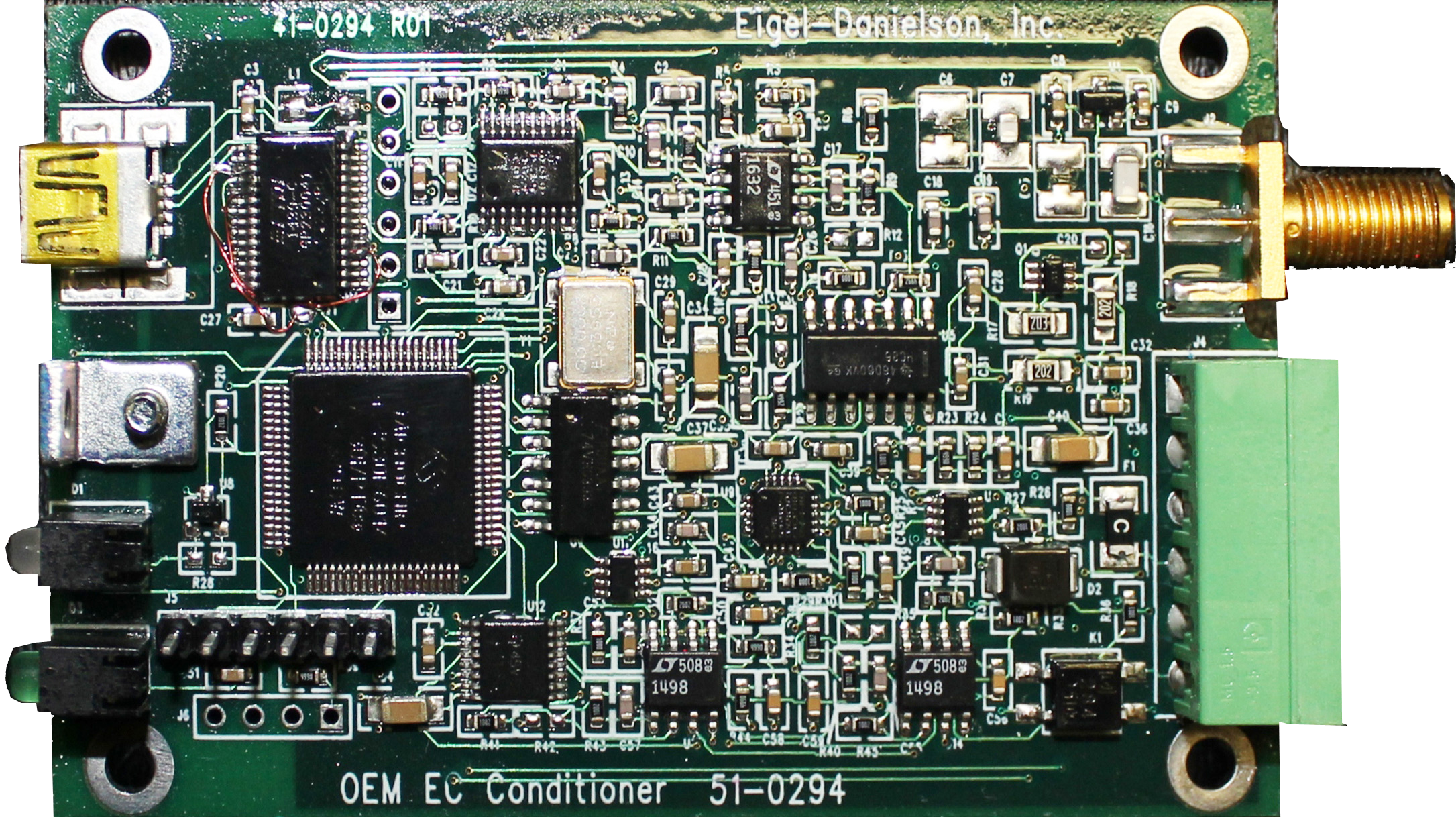

autoEC

Affordable Precision Eddy-Current Conditioning Electronics

The autoEC is an innovative signal conditioning unit designed for high precision passive Eddy Current sensors. Generally these sensors are custom based on the application. This system works with a wide range of coil inductances and cable lengths and is very easy to setup and so is ideal for use in custom sensor configurations. The system can run standalone or with a computer over a USB interface. It delivers high performance via digital, analog voltage (0-5V,0,10V,+/-5V,+-10V) , or current outputs (0-20mA,4-20mA). The system can be setup easily for very short or very long ranges with good performance. The system linearizes and temperature compensates the sensor and electronics to a high degree of accuracy for a total performance package. The system has a sample rate up to 22.5kHz for higher speed applications and allows the easy application of a digital filter for higher resolution.

autoEC Downloads:

autoEC Applications:

- Vibration Analysis

- Position / Displacement Event Capture

- Sizing

- Sorting

- Tracking

- Closed Loop Feedback

- etc.

Will the autoEC work with any inductive sensor?

What is the interface to the sensor?

Can I make my own sensor?

Will EDI make a custom sensor for our application?

Does EDI have a standard line of sensors?

What is the lead time for an autoEC?

Does the autoEC need a computer to work?

Can EDI help me with my application?

Will the autoEC work with capacitive sensors?

Will EDI customize the software specific for the application?